Digital Fabrication “New Equipment”

What is Digital Fabrication?

It is a device which automatically shapes the design data of digital data if material is input. I will reproduce digital data without human’s hand. Many experts do the work that was required, all together, it will be possible to manage constant creation time and quality.

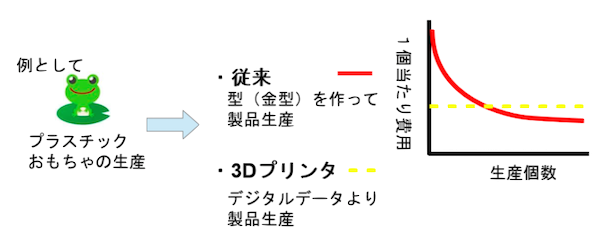

Benefits of Digital Fabrication

1. The complexity is negligible

2. Respond quickly to design change etc.

3. Flexible to respond to the way of production

4. The amount does not change very much with respect to the number of production

Below is an example of one 3D printer of digital fabrication.

Now it is only forming. However, if it becomes possible to synthesize various materials in a complex manner, would not it be possible to create most of the products that are in the rank? Also as individual printers like current printers, it seems that the market of product data will expand. device that does not require many kinds of parts and types> Equipment that has expansion of production method in the future .

Digital Fabrication Something like miniaturizing a manufacturing factory

Subtractive Manufacturing Equipment

Subtractive production equipment is formed by processing the material itself like a lathe. It is used for production processes relatively earlier than additive manufacturing equipment.

Example: laser cutter

We will step up one example product.

· Assembled type laser processing machine FABOOL Laser Mini

Assembled laser cutter made from smartDIYs. For individuals, the main unit price is about 60,000 yen.

Materials themselves cut / scrape (process by shaping)

additive manufacturing equipment

Additive manufacturing equipment is created from materials and formed. It changes the materials themselves according to the shape like casting or resin molding by die.

It is this additive manufacturing equipment that is making remarkable progress now. Using these techniques, we are making from simple resin molding to the house where people live.

Example: 3D printer

Currently, more various 3D printers are coming out, but for the time being we will bring up one example product.

· High speed and high precision 3D printer carbon 3D

We utilize the property of not curing with oxygen which is a weak point of photo-curable resin and light, let the product emerge from resin tank.

It can be made 100 times faster than ordinary 3D printers from 2D technology, and since there is no seam, strength similar to that of injection molding can be developed.

· Low price 3D printer Da Vinci Jr.

A low-priced 3D printer for XYZ Pritting individuals. The main unit price is around 50,000 yen.

· Low price 3D printers for metal 3D printer S1

A low price 3D printer using Aurora Labs metal powder. It can be molded integrally from data by a laser sintering method by burning from powder to laser.

The main body price is around 500,000 yen.

· Building 3D printer Delta WASP

Building 3D printer made by WASP. A gigantic metal frame with a diameter of about 6 m supports the nozzle and is made by stacking clay and mud as a material.