Characteristics and Selection of Aluminum for Machine Parts

I think that I touch things related to aluminum so much as to say always in everyday life everyday.

I would like to explain how to prune with the characteristics when actually using it in development design.

Chemical properties

Aluminum is widely used in general and there are various ways of using it considering chemical properties.

Here I would like to talk about its chemical properties compared to the materials used for mechanical parts.

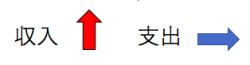

Weight

The specific gravity of aluminum is about 30% of copper, about 35% of iron, about 60% of titanium and about 140% of carbon fiber.

Aluminum specific gravity: 2.7 g / cm 3

Replacing high-speed rotating parts with iron to aluminum will also reduce inertia and improve efficiency.

It is often used to simply lighten the weight.

In order of specific gravity:

copper> iron> titanium> aluminum> carbon fiber

Weight is about 1/3 of iron and copper

Conductivity / thermal conductivity

It has high conductivity and thermal conductivity under normal circumstances.

It depends on state and alloy, but we will explain in roughly.

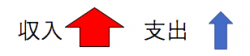

Conductivity

The electrical resistivity of aluminum is about 170% of copper, about 30% of iron, about 7% of titanium and about 0.001% of carbon fiber.

Aluminum electrical resistivity: 28.2 nΩ · m

Copper has better electrical conductivity, but because of its specific gravity the aluminum has better electrical conductivity per weight.

Therefore, the higher the voltage, the more aluminum is used

Electrical resistivity order:

carbon fiber> titanium> iron> aluminum> copper

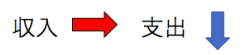

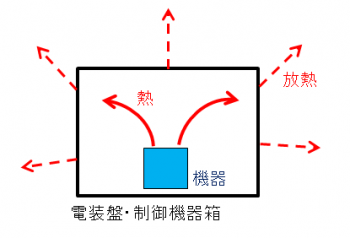

· Thermal conductivity

The thermal conductivity of aluminum is about 60% of copper, about 300% of iron, about 1000% of titanium, about 50% of carbon fiber.

Aluminum products are used in many of the heat transfer products.

The order of thermal conductivity:

carbon fiber> copper> aluminum> iron> titanium

Electrical conductivity is better than copper per weight. Thermal conductivity is also good next to copper.

Chemical properties

· Corrosivity

Aluminum has a high ionization tendency and is susceptible to acid and alkali.

However, it is said that corrosion resistance is generally high, because an oxide film (alumite) is formed on the surface in the air and the inside is protected.

In order of ionization tendency

aluminum> titanium> iron> copper

Magnetic

Aluminum is a weak magnetic material, but you can think that it is almost none.

Therefore, it is also adopted in many measuring instruments.

High corrosion resistance in the air. There is no magnetism.

Mechanical properties

Aluminum is a necessity for mechanical parts by using mechanical properties.

I will explain what it is like.

Strength

The strength of aluminum is low, but the aluminum alloy improves the strength while making good use of lightness and processability, and the application is wide.

It does not show a yielding phenomenon (a phenomenon that the relation between strain and stress does not become proportional and a strain remains even if stress is removed) when deformed when stress is applied. In the case of

The specific strength per unit weight is large, the tensile strength is not large.

Processability

Aluminum has high processability.

It is almost impossible in cutting, cutting and die punching, such as drawing, grinding, bending, welding, etc.

Aluminum can be easily cast.

The melting point is about half that of iron, so castability is high.

High processability, easy casting

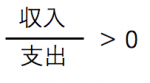

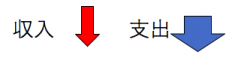

Price

It depends on circumstances and alloys, not everything applies, but it will be below.

In order of price per weight

carbon fiber> titanium> copper> aluminum> stainless steel> iron

Due to the difference in specific gravity, the volume per stainless steel is higher than aluminum.

Aluminum is relatively inexpensive

Other

High radio reflection performance

Aluminum is also good at mirror finishing.

Therefore, it easily reflects electromagnetic waves and visible light.

· No toxicity

Aluminum is said to be non-toxic.

Many foods are also adopted in the field.

· Easy to recycle

Aluminum is easy to recycle.

We use a lot of electricity when making from raw materials, but when recycling

– Powder is inflammable

Aluminum powder may cause dust explosion.

When water is applied to extinguish at the time of burning, hydrogen is generated and damage is increased, so it is strictly prohibited to apply water.

It is designated as a dangerous good under the Fire Law.

It is not toxic and easy to recycle

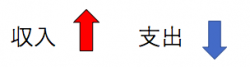

At what time did you choose aluminum?

· Want to lighten

Iron, stainless steel, because it is lighter than titanium, it is very good if you simply want to lighten it. Because the specific strength per weight is also high, replacement design with light weight can be achieved.

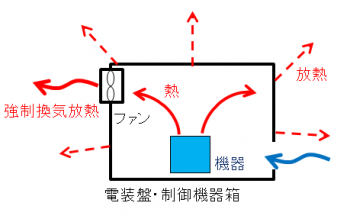

· Want to convey heat as cheaply as possible

Although the thermal conductivity is inferior to copper, the merit as a price is often used for heat sink etc. because it exceeds copper.

· Want to lighten electric cable

Conductivity per weight is better than copper.

However, since it is weak in pulling etc., it can only be used fixed.

There are many others, too.

The use of aluminum is diverse and this is not the limit.

Please try variously in consideration of the situation depending on the situation.

As the material is generalized and the quality is stable, replacement design can be done comparatively easily.

Usage is diverse. Easy to replace

Below is detailed about aluminum as a metal material.

Please refer to those who want to know more detailed contents.

Recycling by Material: Aluminium Recycling, Concrete Recycling, Ferrous Metal Recycling, Glass Recycling, Refrigerant Reclamation, Timber Rec

Standard (alloy)

Aluminum alloy is an alloy containing aluminum as a main component.

Aluminum is characterized by being light, but it is soft, but it can be alloyed with copper, manganese, silicon, magnesium, zinc, nickel or the like to improve its properties as a metal material.

Aluminum alloy can roughly be roughly divided into the rolling (drawing) method and the casting method, and it is a material standard for each application.

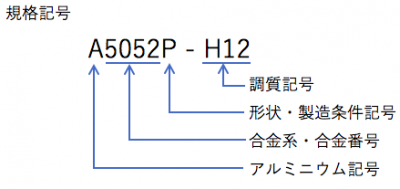

The standard symbol is as follows.

· Aluminum symbol

It becomes the initial letter A.

· Alloy · Alloy number

It will be the number of the alloy. The type of alloy is determined by the number at the head of this number.

· Shape · Manufacturing condition code

P: Plate, disc

PC: laminating board

H: Foil

TW: welded pipe

FD: Die forged wrought goods

FH: Free dedicated goods

Such

– Condition symbol

F: Production as it is

O: Annealing

H: Work hardening

W: Liquefaction treatment

Such

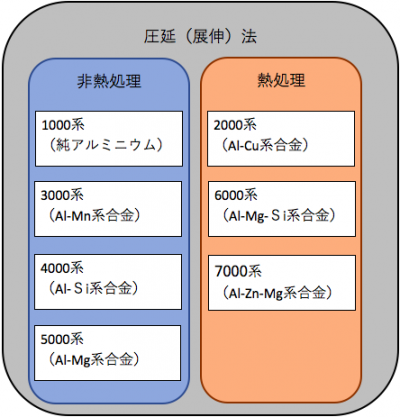

Alloy of rolling (drawing) method

Here, we will explain the standard of “rolling (drawing) method” which is particularly frequently used.

Among the alloys of the rolling (drawing) method, there are non-heat treated alloys and heat treated alloys.

Aluminum alloy of the rolling method is a four-digit number of international aluminum alloy name used.

Commercially available plate thickness is 0.8, 1.0, 1.2, 1.5, 2, 3, 4, 5, 6, 7, 8, 10, 12, 15, 16, 18, 20, 22, 25, 30, 35, 40 , 45, 50 mm.

It is easy to design if you also consider this.

• 1000 series (pure aluminum)

Aluminum purity 99.00% or more Although processability, corrosion resistance, electrical conductivity, thermal conductivity are good, strength is low. It is used as a conductive material or an aluminum foil, and it is not suitable as a structure or machine part.

· 2000 series (Al – Cu alloy)

Duralumin, super duralumin etc. are famous. High strength material comparable to steel material. It is used as a structural material or a forged material but contains copper and is inferior in corrosion resistance.

Weldability is also inferior to others.

It is used in cutting etc. In the case of

A2017: Duralumin

A2024: Ultra duralumin

7000 series with stronger strength and smaller internal stress is used more often than 2000 series which distortion occurs by processing.

3000 series (Al – Mn alloy)

It is the position of the thing raised the strength of 1000 series by adding Mn. A 3003 added Mn slightly increased the strength without reducing the workability and corrosion resistance of pure aluminum. A3004, A3104 further enhance the strength.

• Series 4000 (Al – Si alloy)

Low coefficient of thermal expansion, good heat resistance and abrasion resistance. In the case of

We will process with forging etc.

There are mainly A 4032, A 4043.

• 5000 series (Al – Mg alloy)

It has good corrosion resistance and weldability, and it is also used for cutting work.

The application is very much, it becomes the most balanced alloy among aluminum alloys.

A 5052: It is the aluminum alloy most widely used for mechanical parts.

• Series 6000 (Al – Mg – Si alloy)

It has good strength and corrosion resistance, is widely used for structural materials, and is used for cutting and other purposes.

It is mainly A 6063, A 6061.

• Series 7000 (Al – Zn – Mg alloy)

It is the highest strength in aluminum alloy. Good machinability, but also corrosion resistance weldability is difficult. In the case of

It is used in cutting etc.

A7N01, A7N01: Alloys for welding construction. Relatively high strength and weld strength are restored close to the base metal at normal temperature.

A 7075: Ultra duralumin

The 2000 series, 5000 series, 4000 series, 6000 series, 7000 series used for the structure and machine parts

Alloy of casting method

Below is the alloy standard of the casting method.

As a characteristic, it is almost the same as the alloy of the rolling (drawing) method, so it only lists the name.

It is classified for sand mold type casting and for die casting.

· For sand mold type castings

“AC” is attached to the name

AC1C: Al-Cu alloy

AC2A: Al-Cu-Si alloy

AC3A: Al-Si alloy

AC4A: Al-Si-Mg alloy

AC4B: Al-Si-Cu alloy

AC4D: Al-Si-Cu-Mg alloy

AC5A: Al-Cu-Ni-Mg alloy

AC7A : Al-Mg alloy

AC8A: Al-Si-Cu-Ni-Mg alloy

AC9A: Al-Si-Cu-Mg alloy

· For die casting

“ADC” is attached to the name

ADC1: Al-Si alloy

ADC3: Al-Si-Mg alloy

ADC5: Al-Mg alloy

ADC6: Al-Mg-Mn alloy

ADC10: Al-Si-Cu alloy

ADC14: Al-Si-Cu-Mg alloy

Aluminum is used in many fields in many fields.

I think that better aluminum alloy will be produced in the future.

Below is detailed about aluminum.

Also, as future materials as materials are listed, please try it.